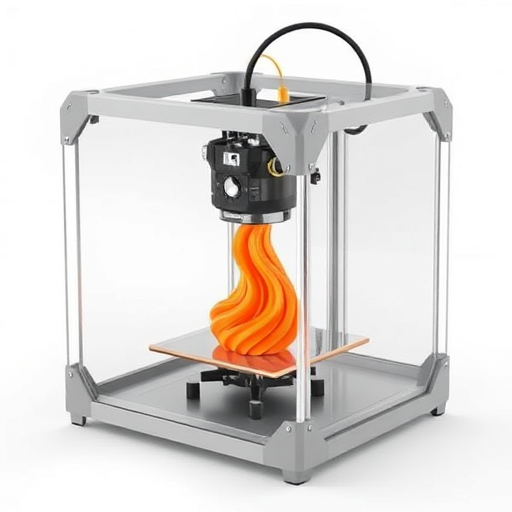

3D printing, also known as additive manufacturing, has experienced rapid growth in recent years, revolutionizing manufacturing, design, and various industries. By allowing the creation of complex structures layer by layer from a digital model, 3D printing has opened up new possibilities for innovation, efficiency, and customization. Here’s a look at how it’s transforming the world of manufacturing and design:

1. Faster Prototyping and Product Development

One of the most significant impacts of 3D printing is in prototyping. Traditional manufacturing methods, such as injection molding or machining, can take weeks to create prototypes, which can slow down the development process. With 3D printing, designers and engineers can create prototypes in hours or days, significantly speeding up the product development cycle.

- Why it matters: Faster prototyping allows for quicker iterations, testing, and refinement, ultimately reducing time-to-market and fostering innovation. It enables companies to test and validate ideas before committing to full-scale production.

2. Customization and Personalization

3D printing offers unparalleled customization, allowing for the production of unique, tailored products. Whether it’s custom medical implants, bespoke fashion items, or personalized consumer goods, 3D printing can create items that meet the specific needs of individuals.

- Why it matters: This customization potential is revolutionizing industries like healthcare, fashion, and automotive, where unique designs and specialized products are in high demand. Consumers are increasingly seeking personalized solutions, and 3D printing allows manufacturers to meet that demand efficiently.

3. Complex Designs and Innovation

Traditional manufacturing methods often struggle to produce intricate, complex geometries. 3D printing, on the other hand, can easily create complex shapes and structures that would be impossible or prohibitively expensive to manufacture using conventional methods. This includes everything from lightweight lattice structures to integrated moving parts within a single print.

- Why it matters: The ability to design and create complex structures opens up new possibilities for industries like aerospace, automotive, and architecture, where lighter, stronger, and more efficient designs are crucial. It also promotes creative innovation in product design, enabling breakthroughs that were previously unimaginable.

4. On-Demand Production and Reduced Inventory Costs

With 3D printing, products can be made on demand, directly from a digital file. This reduces the need for mass production and large inventories, enabling companies to produce parts or products as needed, rather than holding large quantities of stock.

- Why it matters: This shift towards on-demand production can dramatically reduce waste, inventory costs, and supply chain inefficiencies. It also allows for localized production, reducing reliance on global supply chains and enabling faster response times to market needs.

5. Sustainability and Waste Reduction

Traditional manufacturing processes often involve material waste, either due to cutting, machining, or excess materials. 3D printing, however, is an additive process, meaning that material is added layer by layer rather than subtracted from a larger block. This results in much less waste.

- Why it matters: The reduction in material waste makes 3D printing a more sustainable option, especially for industries where materials are expensive or environmentally harmful. Additionally, the ability to recycle or reuse materials in some 3D printing processes contributes to a more sustainable manufacturing model.

6. Distributed Manufacturing and Local Production

3D printing enables distributed manufacturing, where products can be produced locally rather than being mass-produced in centralized factories. This is particularly valuable in industries where customization is key or where logistical challenges make shipping costs prohibitive.

- Why it matters: Localized, on-demand production reduces shipping times, transportation costs, and carbon footprints. It also allows companies to produce parts closer to the end customer, improving supply chain efficiency and reducing the impact of supply chain disruptions.

7. Supply Chain Resilience

The COVID-19 pandemic highlighted the vulnerabilities in global supply chains, with disruptions affecting production and delivery times. 3D printing offers the potential for greater resilience, as companies can produce critical parts or products locally without relying on overseas suppliers.

- Why it matters: This ability to adapt and pivot quickly in response to supply chain challenges gives businesses a competitive edge, particularly when faced with global disruptions or changing market demands.

8. Cost-Effective Low-Volume Production

For small-batch or low-volume production runs, 3D printing can be far more cost-effective than traditional methods like injection molding, which require expensive molds and tooling. 3D printing eliminates the need for these upfront costs, making it a viable option for producing limited runs or prototypes.

- Why it matters: This makes 3D printing particularly attractive for startups, inventors, and smaller businesses who want to produce small quantities of a product without the heavy financial burden of traditional manufacturing methods.

9. Revolutionizing Healthcare

In healthcare, 3D printing is being used to create customized medical devices, prosthetics, implants, and even human tissues. This technology allows for the creation of personalized solutions for patients, from custom-fit hearing aids to tailored orthopedic implants.

- Why it matters: Personalized medical solutions are improving patient outcomes, reducing recovery times, and enhancing overall healthcare quality. Moreover, 3D printing is enabling advances in bioprinting, which could one day lead to the printing of human organs for transplants.

10. Digital Supply Chains and Digital Twins

3D printing integrates seamlessly with digital technologies, allowing for the creation of “digital twins”—virtual models of physical objects. These digital replicas can be used for simulation, testing, and analysis before actual production begins, reducing the risk of errors and improving the efficiency of manufacturing processes.

- Why it matters: This combination of 3D printing and digital modeling allows for more accurate, optimized manufacturing processes, reducing the need for physical prototypes and increasing the speed and accuracy of production.

11. Education and Research

3D printing is transforming education and research by making complex concepts and prototypes accessible. Students, researchers, and engineers can use 3D printers to bring ideas to life and test theories, advancing innovation across a range of fields.

- Why it matters: 3D printing is fostering creativity and hands-on learning in educational settings. Researchers can quickly prototype new technologies, speeding up the pace of innovation and experimentation.